Exploring the NewBeeDrone LionBee 3-Inch Long Range FPV Drone

When I first unboxed the NewBeeDrone LionBee 3-Inch Long-Range FPV Drone kit on a chilly January morning in 2026, a wave of nostalgia hit me—mixing childhood memories of building tiny drones with the thrill of cutting-edge technology. This wasn’t just any build; it was a glimpse into how far micro long-range FPV drones have evolved, blending familiar passions with futuristic features. Join me as I walk through my adventure assembling, flying, and learning from this impressive platform.

TL;DR: The NewBeeDrone LionBee 3inch long-range kit stands out with its robust carbon fiber frame, integrated AIO flight controller, modular 18650 battery system, and impressive flight times, making it a new benchmark for 1S micro long-range FPV drones.

Unboxing the LionBee 3inch Frame and Key Features

On January 8, 2026, I opened the NewBeeDrone LionBee 3-Inch Long Range FPV DIY kit, and it instantly felt like I was stepping into the next era of micro long-range quads. Every piece was thoughtfully packed, and the attention to detail was clear from the start. The LionBee 3inch frame, made from robust carbon fiber, immediately stood out—compact, lightweight, and clearly built for durability and long-range adventures.

The kit included everything needed for a complete build:

- LionBee AIO Flight Controller (with integrated 4in1 ESC, 800mW VTX, and ExpressLRS receiver)

- Sturdy 3-inch carbon fiber frame

- Four 1202 11420KV motors

- Set of Gemfan 3020 props

- BeeEye FPV Camera

- Modular 18650 battery holders (easy to swap and field-serviceable)

- M10Q GPS with a 3D-printed mount

- Small parts: zip ties, rubber grommets, and clear instructions

What really set the LionBee apart was the integration. The AIO flight controller combined the FC, 4in1 ESC, VTX, and ExpressLRS receiver onto a single board. This clever design meant almost no wiring—aside from soldering the motors, the build was nearly plug-and-play. It was a refreshing change from previous long range FPV builds, where tangled wires and complex connections were the norm.

The modular battery holders were another highlight. Swapping 18650 cells in the field was fast and tool-free, making the LionBee practical for long-range missions. The pre-installed M10Q GPS (with a lightweight 3D-printed mount) brought true out-of-the-box navigation support—no more hunting for compatible modules or struggling with custom mounts.

Under the hood, the LionBee’s specs were impressive for its size:

| Feature | Specification |

|---|---|

| Ready-to-fly weight (with battery) | 112.8g |

| VTX Power Output | 800mW |

| Mounting Pattern | 25.5 × 82mm |

With an AT32F435 MCU and ICM42688P gyro, flight stability was excellent. The carbon fiber frame was both compact and crash-resistant, designed for real-world long range FPV. As one FPV expert put it:

“The LionBee set a new standard in micro long-range platforms with its clean integration and durable design.”

Unboxing the LionBee 3inch frame kit was a glimpse into the future of micro FPV—minimal wiring, modular components, and features that make every flight count.

Flight Controller and Reverse Polarity Protection Challenges

From the moment I opened the LionBee DIY kit, the integrated AIO flight controller stood out. NewBeeDrone packed the FC, 4-in-1 ESC, VTX, and ExpressLRS receiver onto one board, making the build almost plug-and-play. This design, powered by the AT32F435 288MHz processor and paired with the ICM42688P gyro, delivered impressively smooth flight dynamics. The 32-bit AM32 ESC MCU handled motor control with precision, and the SPL06 barometer plus current sensor rounded out a feature-rich package.

But with integration comes risk. The promise of reverse polarity protection was reassuring—until I made a simple mistake. In a moment of distraction, I inserted the 18650 battery backwards. Instantly, the flight controller was toast. The current sensor and FC were both damaged, and the quad wouldn’t arm. It was a tough lesson: while the AIO board reduces wiring and complexity, it also means a single error can take out multiple systems.

Support responsiveness became crucial. I reached out to NewBeeDrone, and their team quickly responded with a workaround. By bypassing the damaged current sensor, I could get the quad flying again—though I lost current monitoring mid-test. Their help got me back in the air fast, echoing the advice of seasoned pilots:

“Even the best designs can have moments of human error — what matters is how quickly support can help.” – Experienced FPV Pilot

Determined to restore full function, I tackled a DIY repair. Soldering a 1mOhm 1206 resistor (Vishay Dale WSLF12061L000FE6) across the damaged pads brought the current sensor back to life. It was a small fix, but it highlighted the importance of both community knowledge and manufacturer support in FPV builds.

Firmware setup was refreshingly straightforward. Installing Betaflight 4.5.1 (LIONBEE_V2_REVB target) and flashing the AM32 ESC with LIONB_G_F421 firmware took just minutes. The ExpressLRS SPI receiver bound easily, and the OSD and PID tuning were simple to adjust.

The LionBee’s integrated AIO flight controller is a leap forward in simplicity and performance, but my experience proved that even well-designed reverse polarity protection isn’t foolproof. For anyone building this drone, double-checking battery orientation is a must—and knowing that responsive support and a bit of soldering skill can save the day is just as important.

18650 Battery Performance and Long Range Flight Dynamics

From the moment I slotted a Nitro Nectar Gold 18650 3000mAh cell into the LionBee, it was clear: the battery is the heartbeat of this 1S long-range FPV platform. The choice of cell makes all the difference. Compared to the Molicel P30B, the Nitro Nectar Gold stood out by safely allowing discharge down to 2.7V per cell, squeezing out every last minute of flight time without risking cell health. At just 48g per cell, the weight-to-capacity ratio was ideal for micro-endurance missions.

In real-world testing, I consistently achieved 14–15 minutes of hover time and up to 9 kilometers of range in calm conditions. These numbers weren’t just theoretical—they reflected careful voltage management and disciplined flying. As a Battery Tech Specialist put it:

“It’s as much about the battery discipline as it is the drone design—18650 lithium-ion cells open new doors for endurance.”

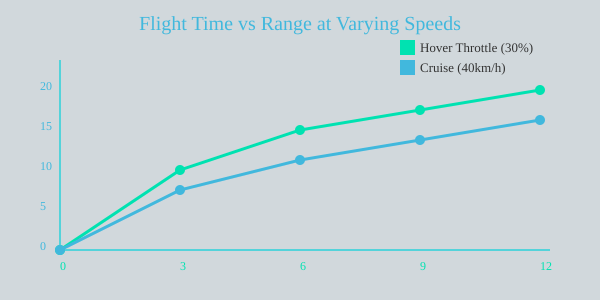

Flying the LionBee was a lesson in efficiency. Hover throttle sat at a modest 30%, and cruising at 40km/h felt smooth and stable, drawing minimal current. Even pushing to its top speed of 75km/h, the quad remained surprisingly quiet and composed. The 1S Li-ion setup demanded a different approach than traditional LiPos—there was less voltage sag, but also less room for error if you pushed the cell too far.

Aerodynamic efficiency and battery quality worked hand-in-hand. Good cells like the Nitro Nectar Gold didn’t just extend flight time—they also enabled safe, deep discharges that are critical for long-range FPV. I found that maximizing endurance was as much about flying smart as it was about hardware: gentle throttle, smooth lines, and constant awareness of voltage.

Long-range flights were further enhanced by the LionBee’s robust GPS and video link. Even well past 800 meters, video transmission stayed strong, and GPS cold-locked in under a minute, building confidence for those far-out explorations.

In summary, the LionBee’s 18650 battery performance set a new standard for 1S long-range drones. With the right cells and careful management, it’s possible to achieve impressive flight times, quiet efficiency, and reliable range—all in a package that weighs just over 110g ready to fly.

Build Experience, Limitations, and Community Insights

Unboxing the NewBeeDrone LionBee 3-Inch Long Range FPV drone kit felt like opening a window into the future of micro long-range quads. The build experience was refreshingly straightforward—almost entirely plug-and-play, with the only soldering required for the motors. Every component was thoughtfully packed, from the robust carbon fiber frame and modular 18650 battery holders to the BeeEye FPV camera and M10Q GPS with a 3D-printed mount. The clear, step-by-step instructions made the assembly process approachable, even for those new to DIY FPV drone builds.

- Plug-and-play assembly: Most wiring was eliminated thanks to the integrated AIO flight controller, 4in1 ESC, VTX, and ExpressLRS receiver.

- 3D-printed TPU parts: While not flashy, these components offered practical durability for real-world flying and crash resilience.

- Customizable firmware: Flashing Betaflight 4.5.1 and setting up the ELRS SPI receiver and AM32 ESC took just minutes, making firmware updates and feature tweaks accessible.

Despite the satisfying build, a few limitations became clear. The LionBee currently supports only analog FPV—there’s no HD camera or digital FPV support out of the box. Adding DJI O4 or similar digital systems would require a redesigned flight controller and frame, plus a beefier 5V BEC. For now, analog video is the standard, but the modular design hints at future upgrade potential.

Another limitation was the lack of a physical buzzer. I compensated by enabling the DShot Beacon in Betaflight, which, along with customized OSD and PID tuning, helped with recoveries and flight performance. Still, adding a tiny buzzer (just 0.7g) is on my wish list for future builds.

Community feedback proved invaluable throughout the process. When I accidentally reversed battery polarity and fried the flight controller, advice from forums and NewBeeDrone support helped me bypass the damaged current sensor and get back in the air. Tips on RX antenna placement, VTX channel selection, and firmware upgrades—like enabling GPS Rescue mode—came directly from fellow pilots’ experiences. As one enthusiast put it:

“Building a drone is as much a social journey as a technical one—the FPV community’s support kept me flying.” – Drone Builder Enthusiast

For anyone considering a DIY FPV drone build, community troubleshooting guides and shared insights are as crucial as the hardware itself. While beginners may find the need for soldering and Betaflight knowledge a hurdle, the collaborative spirit of the FPV world makes overcoming these challenges possible—and rewarding.

Looking Ahead: Wishlist and Future Enhancements for LionBee

Reflecting on my journey with the NewBeeDrone LionBee, I can’t help but look to the horizon and imagine what’s next for this already impressive 3-inch long-range platform. While the LionBee’s thoughtful engineering and robust performance set a new standard for 1S micro explorers, a few key upgrades could truly broaden its appeal and future-proof its design.

First and foremost, the availability of a prebuilt Bind-and-Fly (BNF) drone version would be a game-changer. Right now, the LionBee is a dream for tinkerers, but a BNF option would open the door to newcomers who might be intimidated by soldering or Betaflight setup. Making the LionBee more accessible would grow the community and let more pilots experience long-range micro FPV without the steep learning curve.

On the hardware side, small tweaks could make a big difference. Adding a tiny buzzer—just 0.7g—would make lost drone recoveries far less stressful, especially in tall grass or dense brush. Mounting the RX antenna vertically would boost signal reliability with almost no weight penalty. These are simple, practical upgrades that would enhance usability for everyone.

Of course, the holy grail for many pilots is digital FPV. Right now, the LionBee supports only analog video, but the potential for DJI O4 support is tantalizing. Achieving this would require a beefier flight controller with a stronger 5V BEC and a redesigned frame to fit the 25.5×25.5mm mounting pattern. While this upgrade would add some weight and complexity, it would also bring crisp, low-latency video to micro long-range flying—a leap forward for the entire category.

Firmware updates are another area ripe for growth. Synchronizing with Betaflight 2025.12 could unlock advanced features like Position Hold, making the LionBee even more capable for autonomous missions or failsafe scenarios. At the same time, planning for ELRS firmware continuity is essential to ensure the platform remains compatible with future radio protocols—a must for any serious long-range pilot.

“Innovation thrives when community feedback meets forward-thinking design.” – Drone Industry Analyst

Ultimately, the LionBee’s modular design encourages experimentation and upgrades, but each new feature must balance weight, complexity, and real-world benefit. As the FPV community continues to share insights and push boundaries, I’m confident the LionBee will keep evolving. For now, it stands as a benchmark—one that’s ready to grow alongside the dreams of every pilot who dares to fly further.